[ITEM]

[/ITEM]

[/ITEM]

This is a fairly simple job (it only took me half an hour), but you do need some specialist materials: • Wheel ramps. Do NOT attempt any jobs underneath a car supported just by a jack. People die like that.

That allows you to download all songs you want in mp3 format for free! Mqm new songs mp3 download.

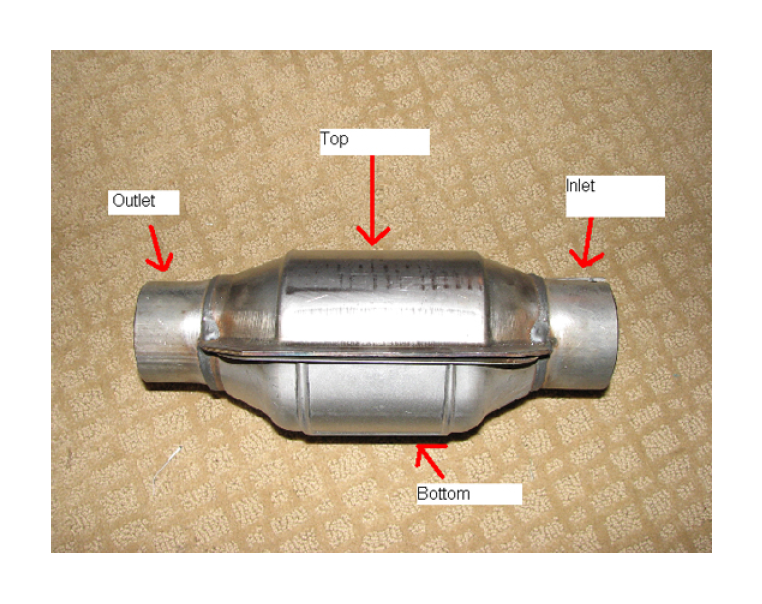

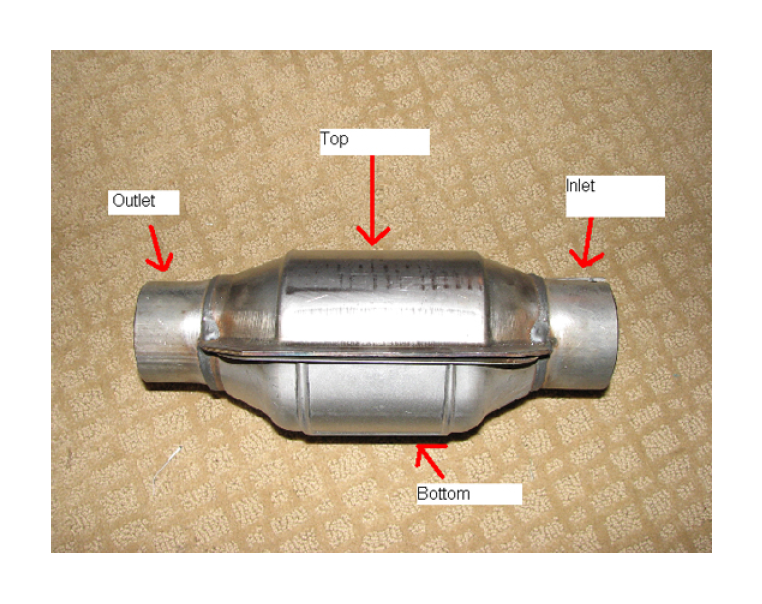

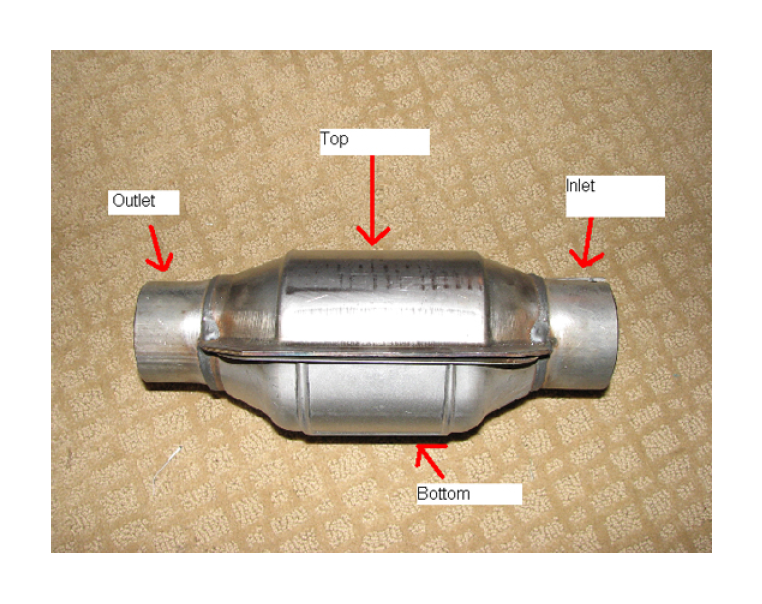

Q: What's the difference between welding catalytic converters in place and placing a sleeve with clamps on it? Asked by Craig P on March 20, 2017 I have to replace my catalytic converters.

• Eye protection (unless you enjoy rust, dirt and toxic chemicals being dropped in your eyes.?)• Metal snips. • Screwdriver (flat-head, to match the jubilee clips). • Assorted pliers, spanners and thumpy things. • (available from any car spares store). • An empty tin can. You should also wear appropriate clothing - spare a thought for whoever does the laundry in your home, and be aware that you could quite easily get un-removable gloop on your clothes.

An old hat might help as well. Unfortunately, my exhaust broke at an odd-shaped bit which meant I had to fix it from the inside out. I used the snips to turn the can into a sheet of steel, then rolled it up to be small enough to fit into the exhaust (be careful of sharp edges, both on the cut can and on the broken ends of the exhaust - tetanus jabs hurt). I slid the rolled can most of the way into the steadier part of the exhaust, with only half an inch (1cm) or so sticking out.

I then pushed the other part of the exhaust into place, and slid the rolled can into that section as well, shuffling it a little at a time by grasping the rolled can with a wide-open plumber's wrench. • If the break had been at a straight section, I could have wrapped the can around the outside of break, locking it in place with a pair of jubilee clips. Although the rolled can completed the exhaust, and took the weight of the looser section, it was not secure enough to move the car, nor was it fume-tight.

I needed to pull the loose section up tight against the fixed section. I put one jubilee clip around the loose section of exhaust, and threaded the second clip through the first, then around the protruding part of the fixed section. Tightening the first clip provided a firm anchor point, then tightening the second clip pulled the broken ends tight together. I then smeared the joint in copious quantities of exhaust fixing paste and left it to set. Unfortunately, I have not found any tool more effective for getting the paste in the right place than the human finger. If you have sensitive or broken skin, you can either use a small spatula or stick, or wear gloves. Once I was happy the whole thing was fixed, I snipped off the loose ends of the jubilee clips, to try and stop loose stuff getting caught under the car in future.

This is a bodge job. It is not a long-lasting repair. It's not great engineering, but it cost about five pounds ($10) for the paste and the clips, and I borrowed the ramps. That's a twentieth the cost of a professional job, and even less should the garage decide you need a whole new exhaust. Add to that the fact that the car only need to last another six months or so, and it's the perfect solution to a problem which would have kept the car off the road for a week, when I need to get to work again on Monday. I am going to try to remain positive here but it's going to be hard. Yes this will help cut down on the noise that your car is making, it is the worst example of home car repair I have see in a while.

Kiteman kudos for trying to fix it and I know it is not ment for a long term fix but see how many people are wanting to do this to pass smog tests and inspections. Not to mention this could cause more damage to the car or cars behind it if something broke and came off the car like the tail pipe. I know the point of all of this is to do a low cost repair but this is even pushing that.

- Author: admin

- Category: Category

This is a fairly simple job (it only took me half an hour), but you do need some specialist materials: • Wheel ramps. Do NOT attempt any jobs underneath a car supported just by a jack. People die like that.

That allows you to download all songs you want in mp3 format for free! Mqm new songs mp3 download.

Q: What's the difference between welding catalytic converters in place and placing a sleeve with clamps on it? Asked by Craig P on March 20, 2017 I have to replace my catalytic converters.

• Eye protection (unless you enjoy rust, dirt and toxic chemicals being dropped in your eyes.?)• Metal snips. • Screwdriver (flat-head, to match the jubilee clips). • Assorted pliers, spanners and thumpy things. • (available from any car spares store). • An empty tin can. You should also wear appropriate clothing - spare a thought for whoever does the laundry in your home, and be aware that you could quite easily get un-removable gloop on your clothes.

An old hat might help as well. Unfortunately, my exhaust broke at an odd-shaped bit which meant I had to fix it from the inside out. I used the snips to turn the can into a sheet of steel, then rolled it up to be small enough to fit into the exhaust (be careful of sharp edges, both on the cut can and on the broken ends of the exhaust - tetanus jabs hurt). I slid the rolled can most of the way into the steadier part of the exhaust, with only half an inch (1cm) or so sticking out.

I then pushed the other part of the exhaust into place, and slid the rolled can into that section as well, shuffling it a little at a time by grasping the rolled can with a wide-open plumber's wrench. • If the break had been at a straight section, I could have wrapped the can around the outside of break, locking it in place with a pair of jubilee clips. Although the rolled can completed the exhaust, and took the weight of the looser section, it was not secure enough to move the car, nor was it fume-tight.

I needed to pull the loose section up tight against the fixed section. I put one jubilee clip around the loose section of exhaust, and threaded the second clip through the first, then around the protruding part of the fixed section. Tightening the first clip provided a firm anchor point, then tightening the second clip pulled the broken ends tight together. I then smeared the joint in copious quantities of exhaust fixing paste and left it to set. Unfortunately, I have not found any tool more effective for getting the paste in the right place than the human finger. If you have sensitive or broken skin, you can either use a small spatula or stick, or wear gloves. Once I was happy the whole thing was fixed, I snipped off the loose ends of the jubilee clips, to try and stop loose stuff getting caught under the car in future.

This is a bodge job. It is not a long-lasting repair. It's not great engineering, but it cost about five pounds ($10) for the paste and the clips, and I borrowed the ramps. That's a twentieth the cost of a professional job, and even less should the garage decide you need a whole new exhaust. Add to that the fact that the car only need to last another six months or so, and it's the perfect solution to a problem which would have kept the car off the road for a week, when I need to get to work again on Monday. I am going to try to remain positive here but it's going to be hard. Yes this will help cut down on the noise that your car is making, it is the worst example of home car repair I have see in a while.

Kiteman kudos for trying to fix it and I know it is not ment for a long term fix but see how many people are wanting to do this to pass smog tests and inspections. Not to mention this could cause more damage to the car or cars behind it if something broke and came off the car like the tail pipe. I know the point of all of this is to do a low cost repair but this is even pushing that.